Supporting computer-controlled milling and turning, Marver Med provides high-quality secondary operations for complete component solutions. Secondary operations are additional machining and finishing processes that follow initial shaping of a component for improved precision, functionality, and appearance, which we perform in-house to significantly reduce overall production time. By providing a range of secondary services, working with us can eliminate delays and added costs of outsourcing to streamline the workflow and increase efficiency with greater control over quality and lead times.

To refine and complete components after primary manufacturing operations, secondary services provide precision techniques for high-quality solutions. With secondary lathes, tool grinders, surface finishing methods, and cleaning and degreasing, our processes ensure your final product is ready for its destination, featuring enhanced accuracy, improved appearances and textures, and removing contaminants for assembly or further processing.

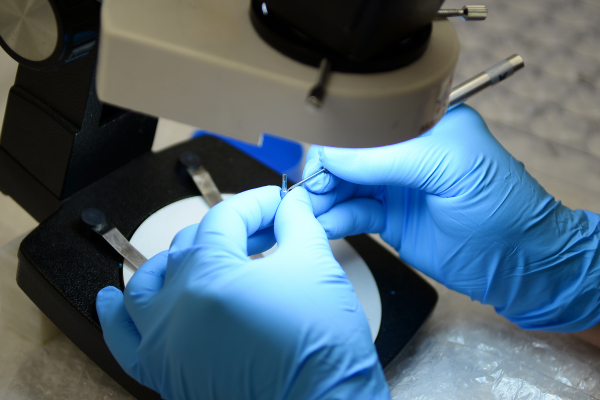

Secondary lathes perform additional machining for parts that have already undergone primary shaping. They can be used for turning, facing, drilling, or threading to refine dimensions, add features, and enhance finishes for versatile and precise operations. Our equipment includes machines that are perfect for small, detailed parts that require fine craftsmanship and high-speed turning operations with superior accuracy, such as:

Operating 2 Clottu grinders, we can sharpen, shape, and refine the surface of your components. They utilize abrasive wheels to remove small amounts of material for smooth surfaces and tight tolerances, delivering precision grinding and ensuring high-quality characteristics.

For surface finishing, we offer glass bead blasting. It is gentle, yet effective for cleaning and surface preparation, creating smooth, uniform finishes. Using fine glass beads propelled at high pressures, this process polishes the component’s surface without removing materials for a satin-like finish on metals, which also improves corrosion resistance.

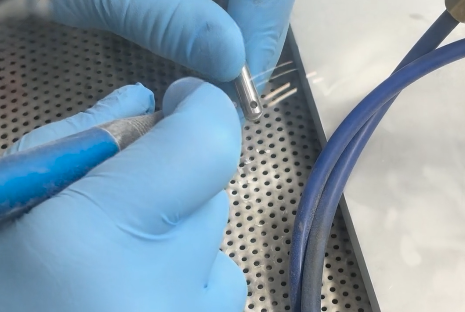

With a Branson Vapor Degreaser and a Branson Ultrasonic cleaner, we are able to provide cleaning and degreasing of your components. The vapor degreaser ensures that parts are thoroughly cleaned to meet stringent cleanliness standards. Additionally, the ultrasonic cleaner offers deep cleaning capabilities for intricate and delicate parts that require extra attention to detail.

Specializing in micro-turning and precision machining of exotic materials, we offer a comprehensive suite of services. Our processes utilize CNC machines for automatic, consistent, and predictable machining techniques, while reducing the risk of operator intervention and human-related errors in production for effective machining of various metals and plastics. Allowing us to complete your project with short lead times and cost-effective operations, our capabilities include:

Marver Med offers precision capabilities to provide high-quality components for demanding industries. Working with you through every step of the production process, we ensure that your components meet specification requirements and operate as intended, meeting or surpassing quality expectations for critical applications. With an established reputation for quality and precision, our continuous innovation delivers superior capabilities for meeting your application needs in the following industries: