Custom Machined Hardware

Many applications in high-performance industries require precision-engineered components for their unique requirements. Often operating under extreme conditions and tight tolerances, components for aerospace, defense, and medical industries play critical roles where failure is not an option, utilizing specialty materials, application-specific designs, and stringent quality control standards to deliver solutions machined to exact specifications.

Marver Med offers capabilities to manufacture custom hardware for operational excellence in challenging applications. Contact us to discuss specifications for custom-machined hardware that meets your requirements.

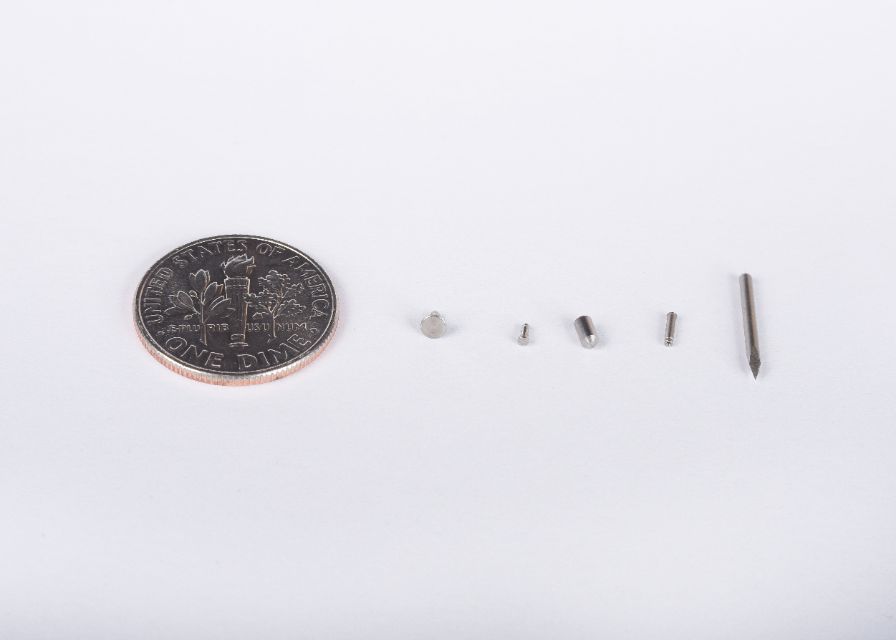

Various Hardware, Components, and Fasteners

Capabilities for Producing Custom Hardware

To meet your needs, we can custom-machine hardware to your specifications or modify existing components. With accurate, predictable, and consistent CNC machining, we reduce the risk of operator intervention and human-related production errors for high-precision custom components, allowing us to meet various specifications. By specializing in micro-turning and precision turning of exotic alloys for custom-machined hardware, the possibilities are nearly endless.

Fasteners & Connectors

- Custom hex, shoulder, eye, J-bolts, and U-bolts

- Specialty machine, socket head, and tamper-resistant screws

- Custom locking, flanged, and wing nuts

- Threaded inserts and studs

- Flat, spring, beveled, and sealing washers

- Bushings and spacers

- Dowel, taper, and spring-loaded pins

- Shafts and rods

- Drilled, tapped, or slotted components

- Custom coatings or finishes for corrosion resistance

- Precision fasteners, locking inserts, and high-strength alloys for aerospace

- Custom engine bolts, brackets, and bushings for automotive

- Surgical-grade screws, orthopedic pins, and titanium components for medical

- Heavy-duty studs, bearings, and wear-resistant hardware for industrial machinery

Precision Components

- Bushings and spacers

- Dowel, taper, and spring-loaded pins

- Shafts and rods

Modified Standard Hardware

- Drilled, tapped, or slotted components

- Custom coatings or finishes for corrosion resistance

Industry-Specific Hardware

- Precision fasteners, locking inserts, and high-strength alloys for aerospace

- Custom engine bolts, brackets, and bushings for automotive

- Surgical-grade screws, orthopedic pins, and titanium components for medical

Materials We Work With for Custom-Machined Hardware

For custom hardware in demanding industries, specialty materials provide various characteristics to meet the needs of critical components. However, these characteristics may also make the materials difficult to machine. By taking a process-focused approach, we examine the material properties to determine the specific machining challenges of a given material to ensure your components are made to your specifications. Our capabilities are compatible with a range of materials, including:

- Invar®

- Monel®

- Steel

- Inconel®

- Kovar®

- Tungsten

- 17—H900 Stainless

- Titanium

- PEEK™

- 52 Alloy

- 300 & 400 Stainless Steel

- KP and KN Thermocouple

- Nitinol

- And More

Custom Machining Solutions from Marver Med Are Quality-Assured

As a precision manufacturer specializing in micro-turning and precision machining, Marver Med is ISO 13485:2016 certified, ensuring satisfaction through every step of a product’s lifecycle while also meeting or exceeding ANSI/ASQ Z 1.4 and military standards and specifications. By monitoring and maintaining control over the machining process, we are a full-service manufacturer with well-documented quality assurance that guarantees your custom-machined hardware matches your exact requirements.

Contact Us for High-Quality Custom-Machined Hardware Solutions

Marver Med offers over 75 years of high-precision CNC machining experience to produce custom-machined hardware to your exact specifications. With the necessary expertise to manufacture high-quality medical devices, implants, and parts for aerospace and defense industries, we can work with a variety of specialty materials for your project while maintaining the accuracy of intricate parts for timely and cost-effective custom solutions.

Contact Marver Med to discuss your custom hardware project,

request a quote to get started, or view our

parts gallery for examples.