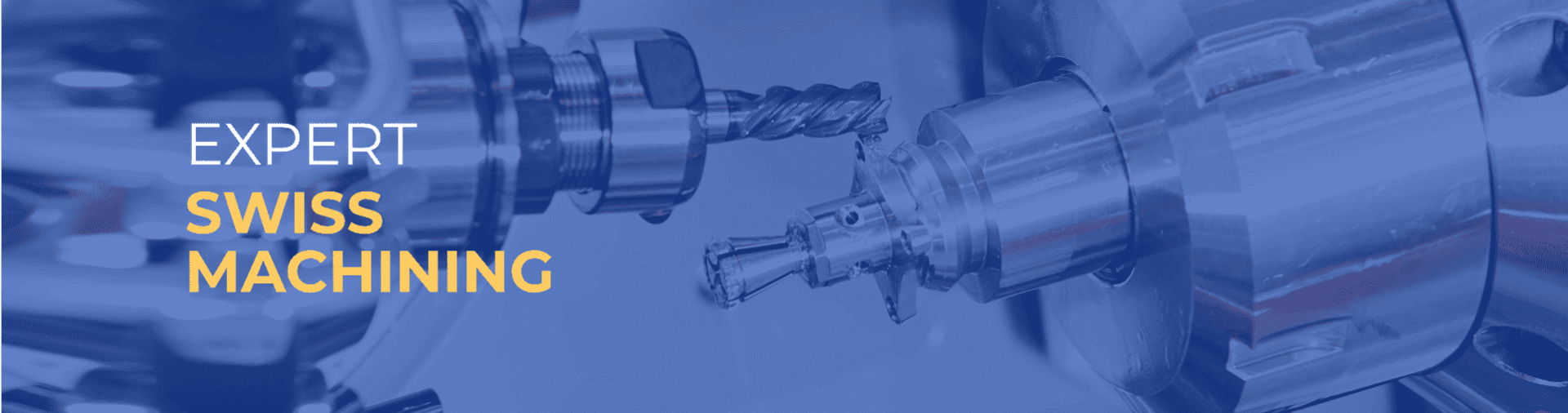

CNC Swiss Machining

We maintain several CNC Swiss machines, producing custom complex or simple components efficiently and accurately. We can produce precision CNC machined components for various applications, including medical devices, aerospace parts, optical equipment, and many more.

CNC Milling

CNC milling has a clear advantage over other alternatives when you need precision parts machined quickly and efficiently. The automated nature, accuracy, and flexibility of CNC milling allows for intricate parts to be rotated in order and machined in a single operation.

Metal Laser Marking & Engraving

We provide custom precision metal laser marking and laser engraving services for any industrial application. Metal laser marking creates shallow markings by melting through the surface of the metal. A common application includes laser marking medical devices. Laser engraving creates deep grooves by evaporating material and is a suited for components that will undergo further processing.

Metal Tube Bending

Metal tube bending requires care and accuracy. We can bend most metal and alloy tubing, including hard-to-work-with materials such as titanium and stainless steel. Our tubes are typically bent incrementally for precise control and to achieve the exact curve your specifications require.

CNC Turning

Our CNC lathes allow us to create completely uniform round, cylindrical, spherical, or conical parts. Shaping, drilling, and tapping operations all occur in one machine arrangement. We create custom products to meet any application through our CNC turning services. CNC turning is used to produce a virtually endless list of components and parts for any industry.

CNC Laser Cutting

Mechanical cutting tools are often too harsh when creating delicate precision components. Our CNC Swiss laser cutting services allow us to cut thin or fragile materials without causing damage or warping. CNC laser cutting does not apply physical pressure during the cutting process, and so it creates well-defined, clean cuts.

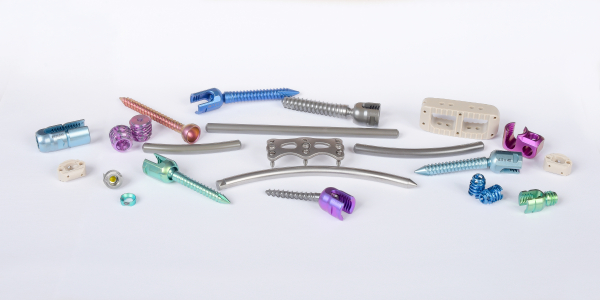

Component Assembly

Marver Med can create custom component assemblies comprised of previously manufactured parts or sub-assemblies. Our highly skilled operators are trained to comply with any safety or controlled environment standard required for your industrial component assembly.

Solid Metal Bending

Every metal or alloy has its own specific yield and tensile strength. We understand how much force is required to bend solid metal while maintaining the integrity of the material. In the past, we have provided industrial solid metal bending services to steel, stainless steel, and many other materials.