Laser marking medical devices and other industrial components creates permanent, contactless designs with endless possibilities. Easy-to-read and durable marks allow for better identification, organization, branding, and more for maximized efficiency and productivity, greater visibility within the supply chain, cost-effective solutions to counterfeiting risks, and displayable compliance with industry regulations.

No matter your goal or application, Marver Med has the expert team and high-precision services needed to deliver your complete satisfaction on every laser marking order. As an ISO 13485:2016-certified company with over 75 years of experience, we are ready to tackle the unique challenges of your project. Contact us or request a quote to get started.

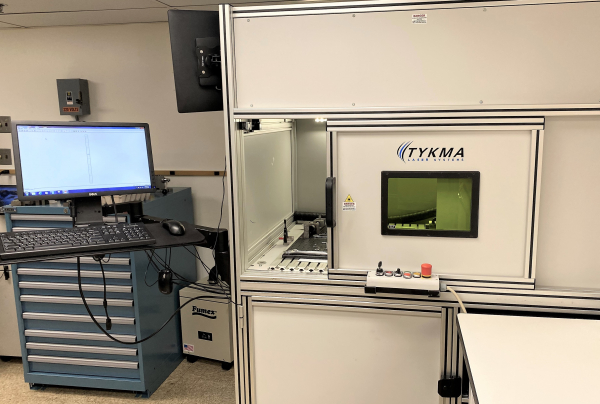

Laser marking creates shallow markings by melting through the surface of a material. It is completed quickly and modifies the material’s surface roughness. As a leading provider of surgical and medical instrument laser marking, Marver Med is ready to meet or exceed your application’s requirements using our cutting-edge capabilities:

Call 781-341-9372 to speak with a representative directly and learn how Marver Med can support your medical facility or other operations through our laser marking services.

Laser marking is most effective when applied to metals or metal alloys. Marver Med has extensive experience laser marking medical devices, aerospace parts, and other industrial components. We have the capabilities and experience to work with:

Laser marking is a fully automated, fast, and cost-effective method for creating permanent marks, designs, or other identifying information on medical devices, surgical instruments, and other industrial components across sectors. Whether you need to meet FDA UDI marking requirements or implement Mil-Spec guidelines, we can help you finish your job on time, in budget, and with complete accuracy.

Laser marking medical devices is an excellent option for creating barcodes, serial numbers, logos, certifications, and other vital identifying information. Marver Med specializes in providing precision solutions for the medical industry, and we have the capabilities to laser mark:

From plane wings to dog tags, laser marking defense and aerospace parts is a cost-effective way to minimize profit loss and recall times. Marver Med routinely works with major aerospace companies, and we are ready to meet strict Mil-Spec guidelines, FAA requirements, and other standards.

With over 75 years of high-precision CNC machining experience, Marver Med has the industrial medical instrument laser marking expertise needed for high-quality results. In addition to our rigorous quality assurance protocols, such as assembling all medical devices in an ISO Class 7 cleanroom, we incorporate your in-house or industry-specific quality guidelines to ensure no detail is missed.

Contact us with questions about laser marking medical devices or other components, or request a quote to discuss your project’s specific parameters.