Nitinol is an incredible super-elastic, shape-memory alloy with conductive properties. Made from titanium and nickel, Nitinol is used to create devices requiring extreme levels of precision. Nitinol is sometimes also referred to as Nickel titanium. Because of its pseudo-elasticity, Nitinol can remember its original shape and retain it when heat is applied.

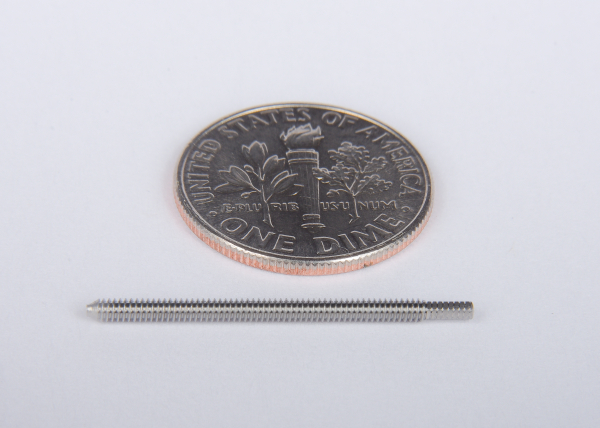

Like many of the alloys Marver Med works with, Nitinol can be challenging to machine. Our expert team has the experience and knowledge to consider all of Nitinol’s properties during machining. Our process-focused methodology allows us to create the quality Nitinol parts you require. In addition to our machining capabilities, we can grind Nitinol as a secondary operation.

Though Nitinol is difficult to machine, the material’s many advantages and benefits make the process well worth it. As well as being super-elastic and conductive, Nitinol parts also feature:

Marver Med will machine custom Nitinol parts to meet your specifications, allowing you to take full advantage of this material’s many strengths and capacities.

While Nitinol parts are instrumental in the medical and orthopedic industries, they are also used in various other projects. For instance, Nitinol is used in orthodontics for brackets and wires connecting the teeth. Other industries and applications that utilize Nitinol parts include:

Nitinol is highly biocompatible, which makes it desirable for medical implants and insertion into the human body. Examples of these Nitinol parts include:

To see examples of custom parts and components we have machined for our past medical clients, visit our Parts Gallery. We can meet any specification, guideline, or regulation required for your precision machined Nitinol part.

Nitinol tubing shares all the benefits, advantages, and challenges of any Nitinol part. These features make Nitinol tubing an ideal solution for many medical devices. Nitinol tubing is commonly used to make:

Marver Med is an ISO13485:2016 certified machining manufacturer. Our quality standards meet or exceed both ANSI/ASQ z 1.4 and Military Standards and Specifications. We are proud to provide complete manufacturing services from concept to production and through fulfillment as your full-service partner. Besides Nitinol tubing and machining, we work with many other challenging materials, such as:

With over 75 years of high-precision CNC machining experience, Marver Med has the component experience needed for high-quality CNC machined medical devices, implants, and parts for the aerospace and defense industries.

Contact us to discuss your Nitinol machining project or request a quote to design your component today.